Automation

After a number of years of manufacturing our own machinery to establish our global sites, we decided to utilise the engineering skillset within Teconnex UK to benefit our customers.

Automation Technologies

Before designing any new machine, we work closely with our customers to fully understand their processes and automation challenges. We review the requirements in detail, identify any pain points, and develop a concept that integrates smoothly into their existing operations. Often, our solutions are designed to speed up production, improve product quality and repeatability, and lower overall manufacturing costs.

We provide automation systems for a wide range of industries and applications (see our core competencies below). Using the latest technologies and components, we tailor each solution to address our customers' specific problems, whatever they may be.

For many years, we’ve also developed custom systems for our own factories. These machines are now operating successfully across four continents. We’ve designed and built equipment used to create parts for leading global companies, including ABB, Daimler, Hyundai, and Cummins, to name but a few.

All our equipment is designed and manufactured in line with all relevant manufacturing standards and legislation.

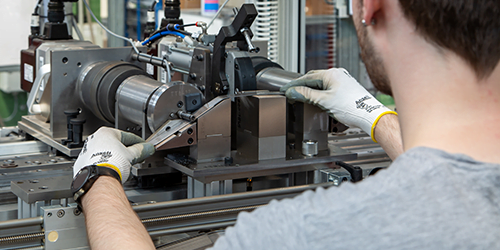

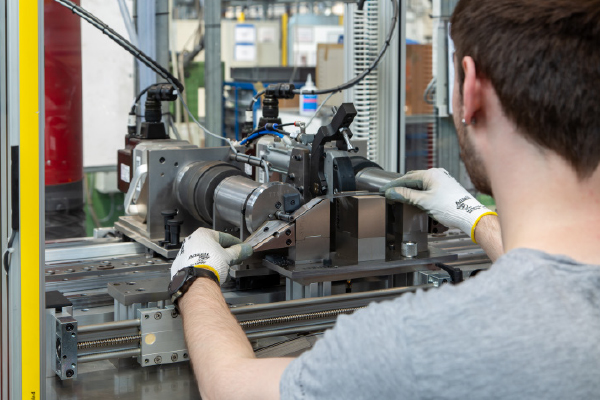

Our custom machinery is built at our 90,000 sq. ft. Teconnex UK facility. Here, our dedicated team handles every stage, from design and manufacture to testing and on-site installation.

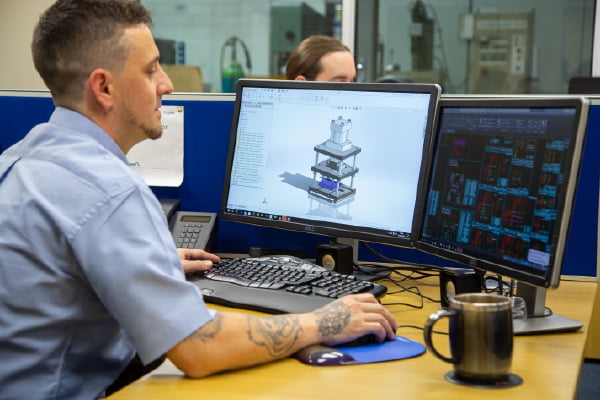

Concept and Detail Design

Progressive Forming

Automated Rolling Machines

Semi Automatic Solutions

Core Areas of Expertise

- Metal Manipulation. Forming, product rolling systems, pressing solutions, integrated welding wells, capping process and control.

- Material Handling and Transfer. Conveyor feed systems, bowl-fed systems, and in-process product orientation.

- Hydraulic Control. Product movement, forming, positioning, lifting, and pushing.

- Pneumatic Control.Product movement, gripping, transfer, safety, and positioning.

- Electrical Control System. PLC control, HMI, control upgrades, safety and interlocking, servo drives and rotation.

- Guarding Systems and Equipment Access.

- Sensing/Vision Packages. Orientation, dimensional confirmation, product movement or transfer.

Bespoke Process Automation Solutions

Control System Design & Manufacture

Automation Integration

Tooling Jigs, Fixtures and Loaders

Our Process

Our UK-based team manages every stage of the design and manufacture of our bespoke machinery solutions. Because we have in-house fabrication and a fully equipped toolroom, we produce most subsystems internally. This reduces our reliance on third-party suppliers, allowing us to maintain complete control over quality and delivery times.

We proudly support UK businesses from within the UK. This approach ensures that our customers receive the best possible after-sales and technical support once the equipment is up and running.

Every machine undergoes thorough testing before it leaves our facility. We are also happy to invite our customers to our facility for machine testing and sign-off, as well as both operator and maintenance training.

You can be confident that every machine we produce meets all relevant safety and industry-specific regulations.

QUALITY ASSURANCE AND TESTING ENSURING OUR STANDARDS

- CE Marking

- 2006/42/EC Machinery Equipment directive

- BS EN ISO 14120:2015 Safety of machinery. Guards

- BS EN ISO 13849-1:2015 - TC Safety of machinery Safety-related parts of control systems

- BS EN ISO 4413:2010 Hydraulic fluid power

- BS EN ISO 4414:2010 Pneumatic fluid power

- BS EN ISO 12100:2010 Safety of machinery General principles for design

- BS EN ISO 14119:2013 Safety of machinery Interlocking devices associated with guards

- BS EN 60204-1:2018 Safety of machinery Electrical equipment of machines

- BS 7671:2018 Requirements for Electrical Installations

- Low Voltage Directive 2014/35/EU

- IET Wiring Regulations